What’s Driving Electric Trucks?

What exactly are electric trucks and why all the hype? Join NACFE and industry experts as we kick off the Electric Truck Bootcamp Educational Series to learn more about the ins and outs of this technology and what is driving its adoption.

In this training, participants will learn:

What’s behind the push toward zero-emission trucks?

What policies exist (or are on the horizon) to support or mandate zero-emission trucks?

How can fleets benefit from electric truck deployment?

Which segments make the most sense for electric trucks today?

Bootcamp speakers include:

Resources

Charging 101 – Planning & Buildout

While much of the attention given to electric trucks is focused on the vehicles themselves, charging infrastructure must be equally considered and planned for. Charging electric trucks can be quite different from traditional diesel refueling processes and presents some unique challenges that fleets, utilities, and OEMs alike need to be aware of.

In this training, participants will learn:

The stages of charging infrastructure procurement, from planning and design to construction and operation.

The difference between Level 2 and DC fast charging power levels and what this means for downtime, electricity pricing, etc.

What business models exist for depot-based charging buildout?

What the future of public charging might look like?

Bootcamp speakers include:

Resources

- Amping Up: Charging Infrastructure for Electric Trucks (NACFE)

- Fleet Decarbonization: A Guide to Cost-Efficient Zero-Emission Vehicle Transition (Black & Veatch)

- US EPA West Coast Collaborative Alternative Fuel Infrastructure Corridor Coalition (WCC-AFICC)

- West Coast Clean Transit Corridor Initiative (WCCTCI)

Charging 201 – Power Management & Resilience

Building out the physical charging infrastructure is only one piece of planning for electric truck charging. There are many additional factors to consider when planning when to charge which trucks at what power levels. Join NACFE and industry experts to learn more about how

to optimize charging to minimize electricity prices while also supporting renewable energy and resilience.

In this training, participants will learn:

What impacts will electric trucks have on the electricity grid?

What standards and protocols exist when it comes to charging?

What tools are available to help optimize charging times and power levels?

Considerations for on-site electricity generation (e.g., solar) and/or battery storage

Bootcamp speakers include:

Resources

Working with Your Utility

Fleets and utilities must work together in unprecedented ways to ensure successful deployment and operation of charging infrastructure for electric trucks. Join NACFE and industry experts to learn more about utility business models and programs and best practices for successfully partnering with your local utility.

In this training, participants will learn:

How are utilities thinking about and planning for commercial fleet electrification?

What programs exist to help fleets plan and pay for necessary charging infrastructure, including grid upgrades?

What factors impact electricity bills, including time-of-use rates, demand charges, and more?

What is a public utilities commission (PUC) and how can you work with yours?

How can electric trucks help put downward pressure on electricity rates for all customers?

Bootcamp speakers include:

Resources

- Trucking Fleet Primer (about utilities) for Commercial Truck Electrification (NACFE)

- Utility Company Primer (about truck fleets) for Commercial Truck Electrification (NACFE)

- Preparing to Plug In Your Fleet: 10 Things to Consider (NRECA, EEI, & APPA)

- Charge Ready Transport program (Southern California Edison)

- Electric Vehicle (EV) Fleet Hub (National Grid)

Run on Less — Electric Videos

Incentives for Electrification

Electric trucks currently cost more upfront than traditional diesel vehicles. And charging infrastructure can also be costly, presenting new expenses for fleets used to diesel fueling. Luckily, incentives are increasingly available for both vehicles and charging infrastructure from the federal government, state and local governments, and utilities.

In this training, participants will learn:

What new revenue streams may electric trucks open up for fleets (e.g. LCFS)?

What sort of financial incentives are available for electric trucks, including grants, rebates, tax credits, and more?

What is the total cost of electrification?

What additional incentives are legislators and regulators currently considering?

Bootcamp speakers include:

Resources

- Funding Finder Tool (CALSTART)

- Advanced Transportation Funding Programs (ACT News)

- New Jersey Zero-Emission Incentive Program (NJEDA)

- National Zero-Emission Truck Coalition (CALSTART)

- Zero Emission Vehicle Awareness Initiative (NRCAN)

- Zero Emission Vehicle Infrastructure Program (NRCAN)

- Federal and State Laws and Incentives (Alternative Fuels Data Center)

Maintenance, Training & Safety

Electric trucks require new maintenance plans and protocols and new training programs for technicians. Safety must continue to be a priority, particularly when working in high-voltage environments. Join NACFE and industry experts to learn more about how the industry is planning to train technicians, drivers, and more to safely operate electric trucks while maximizing uptime.

In this training, participants will learn:

How is operating and servicing an electric truck different from diesel vehicles (e.g., schedules, expenses, etc.)?

Where can fleets turn for training and professional development opportunities related to electric trucks?

What have technicians’ experiences been thus far with respect to electric trucks?

What opportunities exist for those currently working in fossil fuels to transition to the clean energy future?

Bootcamp speakers include:

Financing the Transition & Innovative Business Models

Transitioning to electric trucks and their requisite charging infrastructure will require large investments in new assets. Many questions remain about who will own and operate these assets and how they will be financed. Join NACFE and industry experts to learn about potential financing options and innovative business models.

In this training, participants will learn:

How can fleets finance electric trucks and depot charging?

Who may finance public charging stations?

What innovative business models are currently available or under consideration to help accelerate electric truck deployments?

The scale of capital needed to transition the industry to zero-emission technologies

Bootcamp speakers include:

Resources

- Managed Charging Accelerates Costs & Health Benefits of EVs (AMPLY)

- Financing the Transition – Unlocking Capital to Electrify Bus & Truck Fleets (EDF)

- Taking Commercial Fleet Electrification to Scale: Financing Barriers and Solutions (CALSTART)

- Accelerating Zero-Emissions Delivery: An innovative approach to transforming the last mile (EDF)

Sustainable Supply Chains & End of Life

One of the top motivations for fleets to switch to electric trucks is sustainability, yet questions remain regarding the sustainability of component supply chains — particularly batteries. Join NACFE and industry experts to learn more about what is being done to ensure responsible sourcing and disposal of electric truck components.

In this training, participants will learn:

How can the industry ensure battery components such as lithium, nickel, manganese, and cobalt are sourced responsibly?

What options exist for battery reuse once the battery is no longer able to be used on the truck?

How can fleets ensure safe and responsible recycling of battery components at end of life?

Bootcamp speakers include:

Resources

- Electric Vehicle Batteries: Addressing Questions about Critical Materials and Recycling (Union of Concerned Scientists)

- Metal mining constraints on the electric mobility horizon (McKinsey)

- Effects of battery manufacturing on electric vehicle life-cycle greenhouse gas emissions (ICCT)

- Sustainable Drive, Sustainable Supply: Priorities to Improve the Electric Vehicle Battery Supply Chain (CLEE & NRGI)

- A Vision for a Sustainable Battery Value Chain in 2030: Unlocking the Full Potential to Power Sustainable Development and Climate Change Mitigation (WEF)

- Powering Change: Principles for Businesses and Governments in the Battery Value Chain (Amnesty International)

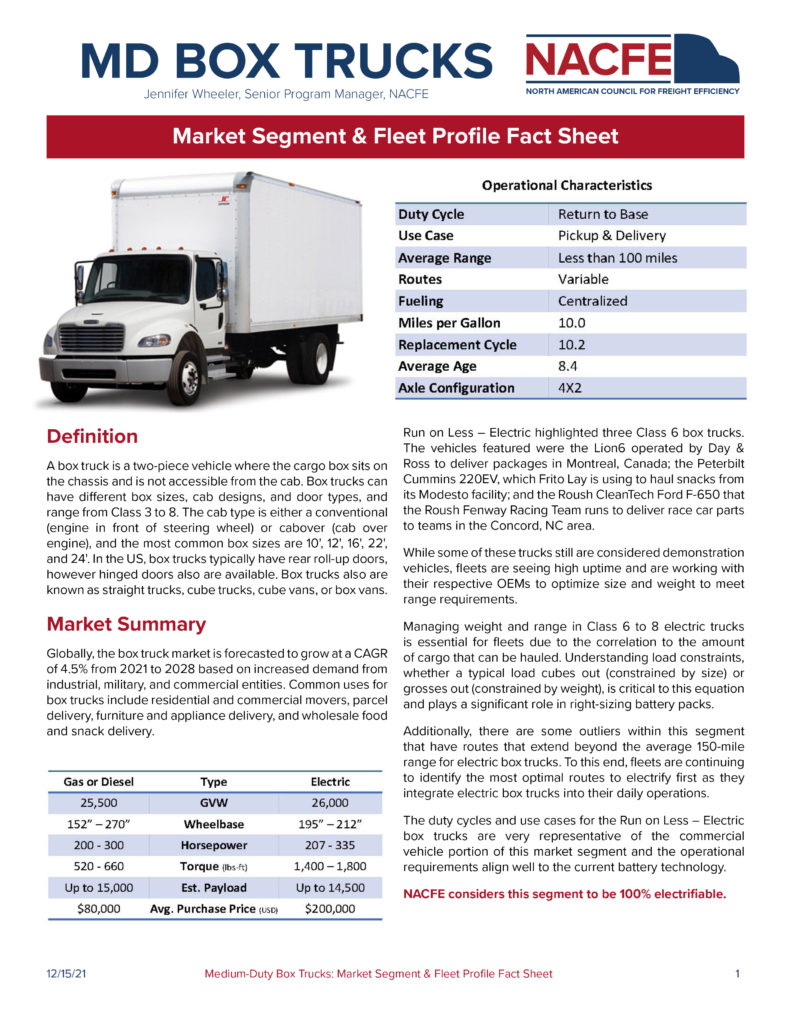

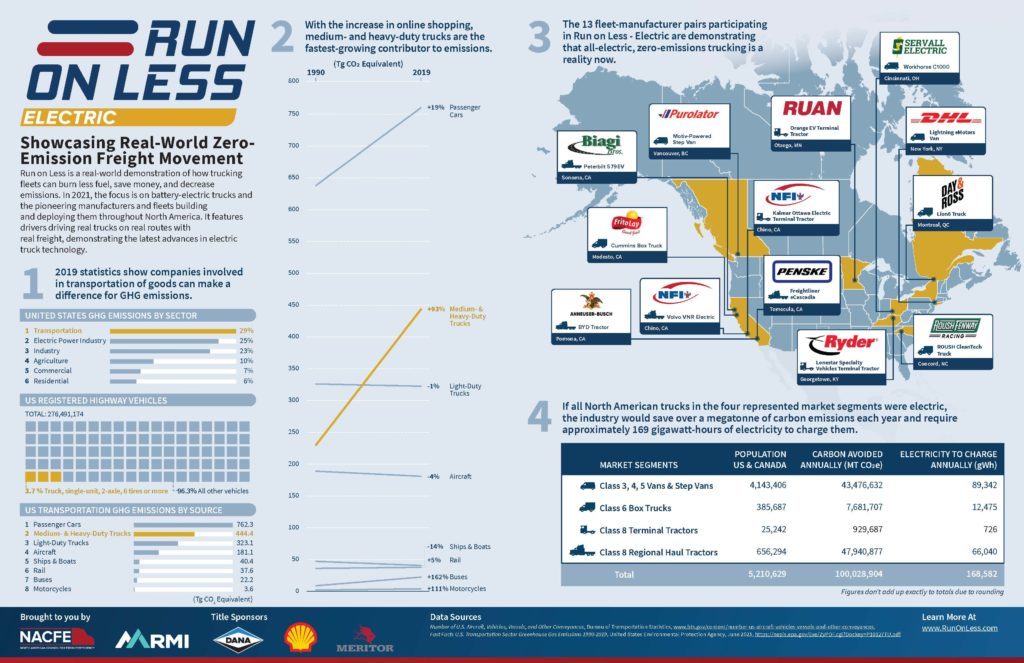

The Use Case for MD Box Trucks

NACFE believes that 100% of the medium-duty box truck market segment will embrace electrification although some applications within the duty cycle will be easier to electrify than others that have more complex bodies. When the simpler box truck portion of this market segment, about 380,000 trucks in the US and Canada, electrifies, it will result in the avoidance of 7,681,707 metric tonnes (MT) of CO2e annually.

Run on Less – Electric Homepage

Global Perspectives

Electric vehicles are being deployed around the globe, not just in North America, where Run on Less – Electric is focused. What lessons can we learn from other geographies and use cases as we develop best practices around electric truck technology, charging systems, and supporting policies?

In this training, participants will learn:

What technologies, business models, and policies have been successful in supporting electric truck deployments in geographies outside of North America?

How is the global trucking industry collaborating on emissions reductions?

What best practices and lessons learned can the trucking industry take away from electric vehicle deployments in other sectors, including transit buses, school buses, vocational vehicles, and passenger cars?

Bootcamp speakers include:

Resources

- Putting Electric Logistics Vehicles to Work in Shenzhen (RMI)

- Fast Tracking Freight in India: A Roadmap for Clean and Cost-effective Goods Transport (RMI)

- Enhancing Urban Freight Systems: A Handbook of Measures on Performance Improvement (RMI)

- Zero Emission Bus Rapid-deployment Accelerator (ZEBRA) (ICCT)

- Global Commercial Vehicle Drive to Zero program (CALSTART)

- Zero-emission Technology Inventory (ZETI) tool (CALSTART)

Drivers and Electric Trucks

Drivers play a critical role in electric truck deployments. Not only is the experience of driving an electric truck different than a diesel, but driver behavior is key to maximizing the performance of these vehicles in terms of efficiency, range, and uptime.

In this training, participants will learn:

What sort of training is necessary for drivers in making the switch to electric trucks?

How does driver behavior impact electric truck efficiency and performance?

What sorts of driver behaviors most impact vehicle performance and how can fleets incentivize these behaviors?

How can electric trucks help fleets attract and retain

drivers?

Bootcamp speakers include:

The Use Case for HD Regional Haul Tractors

NACFE considers the heavy-duty regional haul market segment to be 50% electrifiable with lower average daily miles which results in the avoidance of nearly 29.4 MT of CO2e annually.

The Use Case for Vans & Step Vans

NACFE considers the van and step van market segment to be 100% electrifiable which would result in the avoidance of 43,476,632 MT CO2e annually.

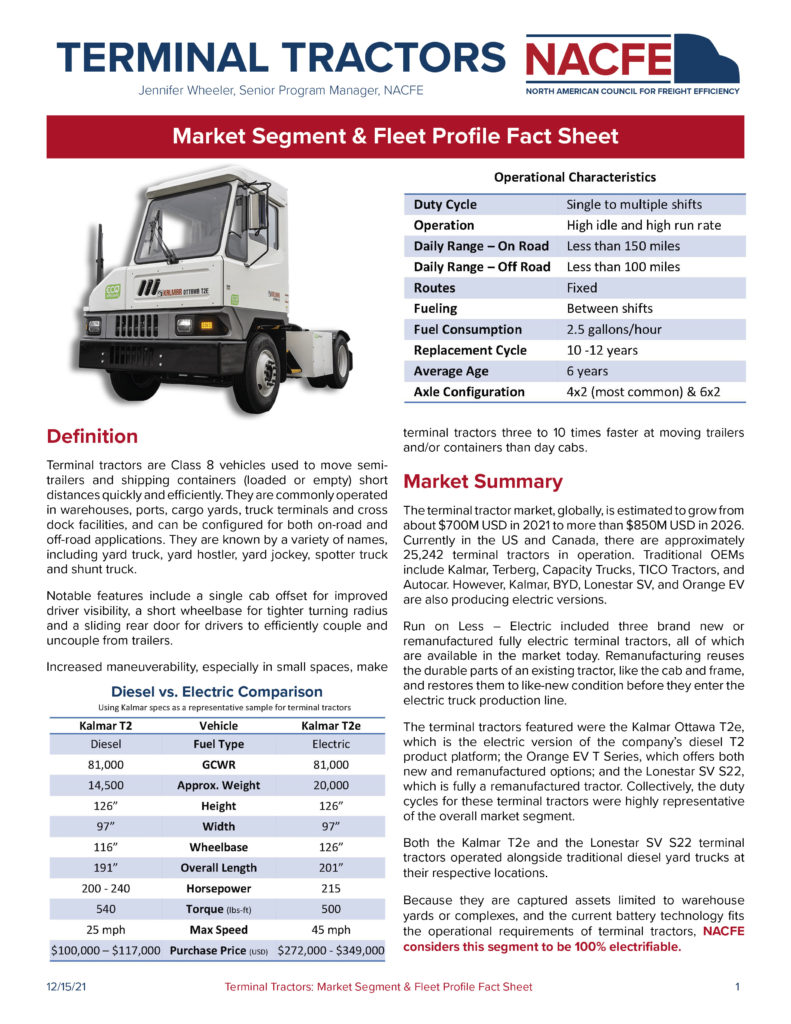

The Use Case for Terminal Tractors

The terminal tractor market segment is the best way for fleets to learn about and implement battery electric vehicles in their operations.

Finale

Data on 13 vehicles shows that it’s time for fleets in certain market segments to make the move to Electric Vehicles.

Diving Into Data

Vehicle metrics on the Run On Less – Electric website provide a great overview of the 13 trucks’ performance during the event. The metrics provide data such as total miles driven and total deliveries made, but they also dig deeper into driving vs. idling time, time in speed range, state of battery charge and more. You can see duty cycle and weather conditions in which a particular vehicle ran and view a truck’s performance on one day or over multiple days. This collection of metrics can give a fleet or any stakeholder an idea of what these trucks can do today.

Environmental Justice

Many communities face pollution daily – those near ports, highways or airports where freight is moved 24/7. Electric trucks provide these communities the opportunity to breathe clean air. EVs also reduce noise pollution because they are extremely quiet. The improved driver work environment that EVs provide allows drivers to experience much less driver fatigue.

Electric Brings Talent

Electric trucks are the new technology of the world. The idea of improving air quality, making trucks safer and the way in which vehicles connect to one another – these factors appeal to younger talent entering the industry. The innovation and the future of #electrictrucks, from a hiring standpoint, attracts the best possible talent from all age groups, genders and ethnicities.

Battery Technology

Battery electric vehicles can be cost competitive or even better than diesel in the right applications. The technology is evolving. New battery technologies take time to go from idea to production. Batteries are becoming more dense, lighter, and charging is becoming quicker allowing for more uses and applications. Similar to a cellular phone or personal computer, the technology will move forward quickly.

Charging Business Models

Regardless of a fleet’s needs, there is a charging business model to help fleets reach their electrification goals: the self-owned and operated option, the charging as a service option (where a third party manages their charging needs), or the electrification as a service model (where a third party manages both their electric trucks and charging infrastructure).

Run on Less – Electric Sponsors

Warehouse Planning

Warehouse planning for EVs is a lot to consider. A fleet must work with its utility to decide where to place chargers and how much charging capacity is needed. Future proofing is important – adding chargers is easier to do once rather than each time you add a new EV. Installing solar panels and battery storage may help offset rates and time-of-use charges.

Truck Driver Appreciation Week 2021

In honor of Truck Driver Appreciation Week – September 12-18, 2021 – NACFE salutes the Run On Less – Electric drivers who are helping us all to learn about electric trucks. And we wish to thank ALL of the hard-working drivers who get people the items they need each and every day. WE APPRECIATE YOU!

Temperature

Temperature does play a role in EV operation. Because there isn’t any exhaust heat from an engine, a BEV needs to generate heat for the cab. As such, a BEV may see a decrease of at least 15% in mileage in winter months. In extreme heat, with additional heat from charging and running the AC in the cab, the battery system may need to be cooled down. Taking into account these extremes, a battery system should be spec’ed with the capacity to get the mileage required on a daily basis.

Electric Truck Education

Bootcamp Trainings

The Electric Truck Bootcamp is a 10-part educational series on electric trucks appropriate for fleet managers, utility planners, policymakers, and more.

While the Run on Less – Electric (RoL-E) event was focused on today’s fleet and OEM leaders who have electric trucks already in operation, the Electric Truck Bootcamp is designed with “fast followers” in mind, to increase industry awareness of electric trucks, provide professional development opportunities to decision-makers at all stages of their electrification journey, synthesize quick takeaways and recommendations from NACFE and RMI’s electric truck work to date, and convene fleets and other stakeholders across the electric truck ecosystem to discuss key opportunities and challenges as they plan for future deployments of electric vehicles.

The Electric Truck Bootcamp was conducted via virtual trainings held biweekly from April through August 2021 leading up to RoL-E. The Bootcamp was free to attendees thanks to the generous support of RoL-E sponsors. Each training was recorded and is available for viewing via the links below.

Attendees can demonstrate comprehension of the material — via optional online quizzes following each training — and have the opportunity to earn digital badges that recognize their expertise and which can be shared via attendees’ social networks. Badges are available for those who complete one, five, or 10 trainings via runonless.com. Participation in the quizzes and badging system is not required for participation in the Bootcamp trainings.

For questions related to the Electric Truck Bootcamp, see our FAQs. For any additional Bootcamp questions, please contact Dave Schaller.

Grid Capacity & Readiness

Resiliency of the grid requires having plans in place with your utility. Start working with your utility as early and often as possible when considering the switch to #electrictrucks to ensure you both are working within the same timeline and toward the same goal. Developing a relationship with your utility early helps them prepare infrastructure as your fleet grows.

Join our email newsletter and you’ll be entered to win a FREE Run on Less – Electric hat from NACFE. Scroll to the bottom right of this page to enter to be one of five winners during the month of September 2021.

About Run On Less — Electric

What is Run on Less – Electric?

Run on Less is a best-of-the-best demonstration that showcases advancements in freight efficiency spread across two countries.

The North American Council for Freight Efficiency (NACFE) and RMI will be conducting Run on Less – Electric (RoL-E), an electric truck technology demonstration in 2021. Commencing in September of 2021, the three-week demonstration will showcase electric trucks in everyday operation.

RoL-E demonstrates how efficiency technologies improve the bottom line for fleets and benefit the environment by reducing greenhouse gas emissions.

Each Run highlights a specific trucking segment and details how these drivers and fleets deliver high efficiency.

In September 2017, NACFE worked with seven fleets and numerous supporting suppliers on the original Run on Less to determine a benchmark for best-in-class fuel economy. Run on Less Regional was held in October 2019 with a focus on trucks that operate 300 miles from base.

Both Run on Less Regional and Run on Less 2017 featured real-time monitoring of a number of factors including miles traveled, fuel consumed, pickups and deliveries, elevation change, and vehicle speed among others.

Run on Less is made possible thanks to the support of fleets volunteering to take part in the demonstration and sponsors helping to underwrite the costs associated with it.

To learn more about Run on Less, contact us:

contact@nacfe.org

Total Cost of Ownership

Total cost of ownership, or TCO, is a major factor in deciding to purchase a new truck. The TCO for electric trucks has yet to be determined. Run On Less – Electric fleets have seen improvements in operating efficiency and uptime. They expect EVs to have a longer in-service life – at least 10 years. Intangibles, like reducing driver fatigue, are another benefit. In the not-so-distant future, the TCO of an EV is going to be at parity or better than diesel.

Early Adopters

We don’t learn without doing. Early adopters help OEMs, utilities, fleets, drivers and municipalities learn about new technology challenges and hurdles. They invest the time and money to make new technology successful and contribute to improvements that will help pave the way to wider adoption.

Charging Infrastructure

Charging is specific to a fleet, site and case. Planning charging infrastructure needs to take into account many factors – site, fleet, vehicle, power, charger, software – and should include conversations with the utility provider to find the configuration that works best for a particular fleet. Advice is to start the conversations on infrastructure early, when first considering electric trucks.

Join our email newsletter and you’ll be entered to win a FREE Run on Less – Electric hat from NACFE. Scroll to the bottom right of this page to enter to be one of five winners during the month of September 2021.

Drivers Love Electric

What do Run On Less – Electric drivers say about EVs? They’re quiet – there’s no need to crank up the radio and drivers can hear what’s going on around them. Visibility is great. Cleaner, simpler operation – no diesel fueling – just plug it in and it’s good to go. Torque is much smoother. Driving in traffic seems easier and safer. The AC is amazing. We’d say they are loving their electric trucks!

Maintenance & Uptime

An EV powertrain has fewer moving parts than its ICE powertrain counterpart. Removing the diesel engine and aftertreatment systems eliminates a huge chunk of typical truck maintenance costs and downtime. Auto makers believe they are seeing 30% to 40% less in maintenance expenses with EVs. With no need for oil changes or DPF fluid, the hope is that will transfer to commercial vehicles as well.

Join our email newsletter and you’ll be entered to win a FREE Run on Less – Electric hat from NACFE. Scroll to the bottom right of this page to enter to be one of five winners during the month of September 2021.

Range & Weight Anxiety

Range anxiety is a piece of looking at electric trucks. These current applications have lower range requirements. Range will be extended in the next generation of electric trucks, and we’re learning that weight doesn’t always matter.

Run on Less – Electric

In September 2021, NACFE worked with 13 fleet-OEM pairs and numerous supporting suppliers to stage a demonstration with commercial battery electric vehicles (CBEVs) in four market segments — vans and step vans, medium-duty box trucks, terminal tractors and heavy-duty regional haul tractors. The trucks operated in eight states or provinces in the US and Canada.

The purpose of the Run was to demonstrate the viability of currently available CBEVs in these market segments and to encourage fleets to make investments in production CBEVs.

These market segments are estimated to contain 5.2 million vehicles. Annual greenhouse gas emission savings from electrifying these market segments are estimated to exceed 100 million metric tons (or 1 megatonne) of CO2.

A VIDEO RECAP OF RUN ON LESS – ELECTRIC

The third NACFE demonstration showcased advancements in freight efficiency, this time with commercial battery electric vehicles.

Download the Run on Less – Electric report here

Market Segment Reports

View the Run on Less – Electric Fleet Profiles here

View the Run on Less – Electric Metrics here

View the Electric Truck Bootcamp trainings here

Results By Truck:

“Run on Less – Electric takes the ‘nervousness’ out of electric trucks for fleets. They can see these trucks are out there running today and not just something you see on the trade show floor.”

AMANDA PHILLIPS, GENERAL MANAGER OF OEM SALES, MERITOR

“RoL-E demonstrated that for four market segments — vans and step vans, medium-duty box trucks, terminal tractors and heavy-duty regional haul tractors — the technology is mature enough for fleets to be making investments in production CBEVs.”

MIKE ROETH, NACFE EXECUTIVE DIRECTOR

Market Segment Fact Sheets

Title Sponsors

Event Sponsors

Supporter Sponsors

Running in the Real World

The Run is REAL. The real world has weather, mountains, deserts, cities, delays, hours of service, inspections, downtime and more. The real world is really tough on trucks.

The Story So Far…

The Run has begun, and here is what we have learned so far.

Day & Ross and The Lion Electric

Just as Olympic athletes must be prepared to compete in extreme weather conditions, this Montreal EV will face harsh conditions like snow and cold temperatures. The final Run on Less – Electric fleet video is the Day & Ross and The Lion Electric team.

NFI Industries and Kalmar

Second-generation driver Jazmin Vazquez uses an electric terminal tractor to shuttle trailers around an eight-building campus making multiple runs per day. Today’s featured Run on Less – Electric fleet is the NFI Industries and Kalmar team.

The Story So Far…

We are right in the middle of Run on Less – Electric. The demonstration features three phases. First, was the Electric Truck Bootcamp Training Series, where industry experts shared their knowledge about EVs. In Phase 2 NACFE team members visited all 13 fleets in the Run and talked with more than 90 people directly involved in operating these EVs every day. Phase 3 is the Run itself, which starts September 2. Get engaged today and follow the Run right here on runonless.com

Servall Electric and Workhorse

This third-generation electrical construction company has “put its money where its mouth is” and uses an electric step van to install EV car chargers in the Cincinnati area. Today’s Run on Less – Electric fleet video features the Servall Electric and Workhorse team.

Ryder and Lonestar Specialty Vehicles

An electric terminal tractor jockeys hundreds of trailers around a major automotive plant in Kentucky every day of the week. Today’s new Run on Less – Electric fleet video is with the Ryder and Lonestar Specialty Vehicles team.

Purolator and Motiv Power Systems

The first Canadian company to deploy a fully electric last-mile delivery truck is striving to be the greenest courier company in a city committed to environmental leadership. Learn more about today’s featured Run on Less – Electric fleet Purolator and Motiv Power Systems team.

NFI Industries and Volvo Trucks

Moving containers from the Inland Empire to the Port of Long Beach, NFI runs Class 8 BEV tractors in drayage daily, negotiating very dense urban areas. Meet today’s featured Run on Less – Electric fleet, the NFI Industries and Volvo Trucks team.

Anheuser-Busch and BYD

Eight electric heavy-duty Class 8 tractors deliver beer in urban Los Angeles every day. Beverage tractors – even with their heavy loads – are an early adopting BEV application. Meet today’s featured Run on Less – Electric fleet Anheuser-Busch and BYD.

Roush Fenway Racing and ROUSH CleanTech

The first carbon-neutral-certified race team in the US leads in sustainability, delivering parts and more using an electric box truck. Our Run on Less – Electric video spotlight for today is the Roush Fenway Racing and ROUSH CleanTech team.

Penske and Freightliner

Collaboration is the name of the game when it comes to electrification. Today’s new Run on Less – Electric fleet video is with our Penske and Freightliner team. They are learning fast what is needed for regional haul EVs in Temecula, CA.

DHL and Lightning eMotors

Electrifying the last mile is NYC DOT’s goal. Today’s new Run on Less – Electric fleet video is with our DHL and Lightning eMotors team, who is moving fast to electrify every truck at its NYC depot, where electric vans deliver packages in the final mile in Manhattan.

Frito-Lay and Cummins

2 football fields of solar panels on one site! Today’s new Run on Less – Electric fleet video is with our Frito-Lay and Cummins team. Frito-Lay is transforming its Modesto, California complex to be a near zero emissions facility.

Biagi Bros. and Peterbilt

Today’s new Run on Less – Electric fleet video is with our Biagi Bros. and Peterbilt team. Driver Pat Brandon says, “What a great feeling to know that I am not polluting – that I am doing something for the future.”

Ruan and Orange EV

Run On Less – Electric fleet videos kickoff here and now with our Ruan and OrangeEV team. They were the first to be filmed so we are sharing them with you first too. “Game changer” in the words of an extremely talented driver.

Watch for more videos over the coming weeks!

NACFE Team Members Visit Participants

We’re about halfway through our site visits to interview the fleet executives, drivers and OEMs that are participating in the upcoming Run on Less – Electric.

Watch for more videos and profile information coming in August!

Department of Energy Fireside Chat

Run on Less – Electric

Run On Less – Electric 2021 Promo from NACFE on Vimeo.